The Best Guide To Dust Extractors For Small Workshops

Wiki Article

The smart Trick of Dust Extractors For Small Workshops That Nobody is Discussing

Table of ContentsDust Extractors For Small Workshops Things To Know Before You Get ThisThe 2-Minute Rule for Dust Extractors For Small WorkshopsThe Of Dust Extractors For Small WorkshopsThe Single Strategy To Use For Dust Extractors For Small Workshops

The obstacles for shop dust collection systems rotate around crystalline silica dirt, carbon monoxide gas, and also heat, which are harmful mixes. These factors make conference air high quality standards challenging and demanding. When choosing a dirt control system for a foundry, the first consideration is the capacity of the device to hold up against severe as well as unsafe workplace conditions.

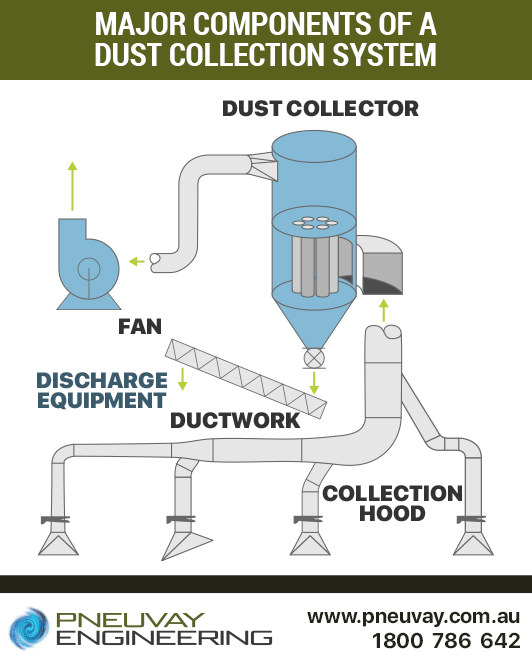

Coating, or thermal spray, applies warmed product to steels to coat their surface areas. Dust collection systems for this sort of procedure should be specifically created to fit the sort of covering being applied. The purpose of the system is to manage and lessen overspray and also dust. The typical thermal spray dirt control system makes use of ducts to relocate air to the collection tool. dust extractors for small workshops.

Though it would certainly appear likely to raise air movement as well as movement, this type of option may mishandle as well as waste energy. The design of the cubicle relies on the force of the air getting in the cell or booth. For most systems, it is vital to have a slight vacuum in the booth to prevent feasible favorable pressure.

A Biased View of Dust Extractors For Small Workshops

An additional method is simply putting the makeup air link on the top of the booth. No matter of the layout, it is important for the cleaning of the air to have cross ventilation. Just like a cleanroom, air movement in a thermal spray booth can be either straight or downward, though the downward style is best for dirt collection systems.The pharmaceutical industry is a highly regulated industry with extensive as well as accurate laws. Dirt from drugs is generated mainly during the production and also product packaging of items. Each action of producing a medicine, which consists of granulating, drying out, mixing, pushing, finish, and grinding, generates large amounts of dust that need to be eliminated.

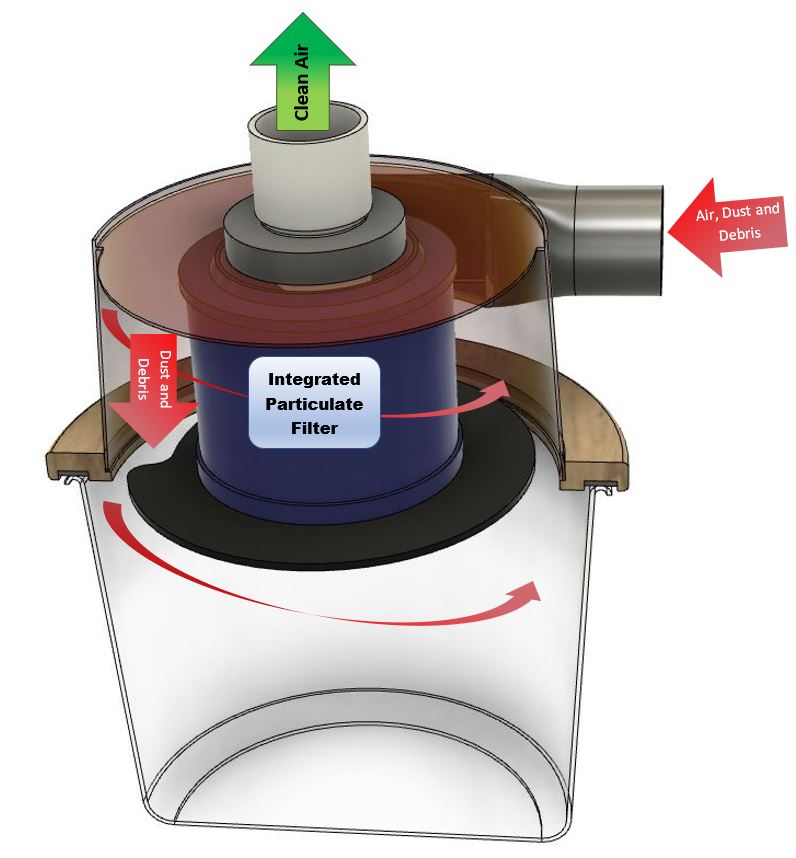

Intercepting and controlling this circulation is the feature of the dust control system. When developing a dust control system for a pharmaceutical plant, the initial consideration is mapping the air flow system to track the path of dust, fumes, existing air flow patterns, as well as feasible transformative changes. Considering that several pharmaceutical dusts are flammable, the style of the ventilation system is extremely critical.

HEPA filters are generally discovered in pharmaceutical dirt control systems given that they are the most efficient as well as reputable. As with a factory system, they are installed as a secondary security to attain zero discharges. Recycling creates a lot of dust as a natural end result of reducing things to their basic materials.

3 Simple Techniques For Dust Extractors For Small Workshops

Dirt originates after materials are shredded, top article squashed, or have paint or lacquer got rid of. All reusing centers are needed to stick to air high quality criteria. As they function to meet quality requirements and control pollutants, they have actually identified that dirt control is a major concern, bring about the broad usage of dirt this post collection systems to mitigate and also consist of the trouble. dust extractors for small workshops.When suppliers choose a dust control system, they are suggested by producers concerning the kind of system that would best fit their needs because buying as well as installing a dust control system is a significant financial investment. Particulate issue comes in a wide array of forms, from silicon dirt to timber chips as well as sawdust.

Excitement About Dust Extractors For Small Workshops

Material filter bags in a cartridge system are the most efficient method for gathering dust. Dirt collection systems are covered to contain the dust and tidy the air.Plastic Dirt High-Density Polyethylene (HDPE) dust is created in the production of plastic panels when they are shaped as well as created on an edge leaner, grinder, or miter saw. Paper Dirt One of the extra common kinds of dust is paper dust, the adverse effects of the production of various kinds of paper.

With the introduction of dirt collection systems, workers are more secure as well as a lot more secured. Sugar Sugar dirt is the by-product of the manufacturing of candy. Pulse jet systems are used to keep the filters of the dust collection system particulate-free. The gathered product is removed as well as accumulated in drums. Zinc Zinc dust is produced in the galvanizing procedure.

A baghouse system is the favored system. Rice Dirt Rice dust has very fine and minute particles that accumulate during the manufacturing of blog rice-based items. A dirt collection system is required for the protection and safety and security of workers. Silica Silica is just one of the most typical compounds on earth. It is a main part of several manufacturing operations, such as the production of glass, ceramic tile, cement, and also asphalt.

Report this wiki page